Capacity: 8 ton per hour steam output

Pressure: 1.25Mpa (12.5bar)

Place of Origin: China

Brand Name: ZOZEN

Certification: ISO, CE, ASME

Minimum Order Quantity: 1 set

Price: Contact Us for Latest Price

Payment Terms: L/C, T/T

Packaging: Nude packing with foam for boiler body, wooden case for boiler accessories.

Detail Information

- Output: Steam

- Range of Capacity: 1 ton – 20 ton (64BHP – 1280BHP)

- Fuel Design: Nature gas, coke oven gas, biogas, liquid propane gas, diesel, heavy oil, light oil, crude oil, etc.

- Design Pressure: 0.7Mpa – 1.6Mpa(101.5PSI – 239.3PSI)

- Warranty: 1 Year

- Structure: horizontal two pass fire tube boiler

- Factory: ZOZEN boiler Co., Ltd.

- Application: Heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital etc.

- Style: Packaged boiler

- Design Efficiency: High Effciency 95%-99%

- Condition: New

- Use: Industrial production line

- Product Name: 8 ton gas fired steam boiler

More Detial of This 8 Ton Boiler

8 Ton Gas Boiler Site

Details of Gas Boiler

Control System of 8 Ton Boiler

Gas Fired Steam Boiler Introduction

- Model: WNS

- Capacity: 1-20 ton/h (64BHP – 1280BHP)

- Design pressure: 0.7/1.0/1.25/1.6/2.5Mpa(7/10/12.5/16/25bar)

- Stem temperature: 184/194℃

- Design fuel: natural gas, lpg,lng,cng,city gas,biogas, diesel oil,heavy oil,etc

WNS series fuel gas steam boiler is a shell-type horizontal boiler. It has the characteristics of compact structure, small size, high degree of automation, convenient installation, safe and reliable operation, and sufficient fuel combustion. It is of great help to the production of various industries. It is widely praised by chemical plants, printing and dyeing plants, heating industry and so on.

This 8 ton boiler has the advantages of full combustion, no pollution, convenient operation, convenient installation, etc.; this type of boiler has high thermal efficiency, large output, strong load adaptability, high degree of automation, convenient operation, safe and reliable operation, and it is a kind of Ideal high-efficiency, low-consumption, low-pollution and green environmental protection products.

Core technology

- Nitrogen oxide emissions<30mg/m3

- PLC control system

- The 5th stage water level protection

- Flame-out,power failure self-locking protection function

- Automatic fault identification function

- Data collection analysis function

- Internet og Things remote monitoring

Product Parameters

| Model | Rated steam capacity(t/h) | Rated working pressure(Mpa) | Rated steam temperature(℃) | Maximum transport size(m) (L×W×H) |

| WNS1-0.7-Y(Q) | 1 | 0.7 | 170 | 3.3×1.8×2.1 |

| WNS1-1.0-Y(Q) | 1 | 1 | 184 | 3.3×1.8×2.1 |

| WNS1.5-1.0-Y(Q) | 1.5 | 1 | 184 | 3.0×1.8×2.0 |

| WNS1.5-1.25-Y(Q) | 1.5 | 1.25 | 194 | 3.0×1.8×2.0 |

| WNS2-1.0-Y(Q) | 2 | 1 | 184 | 4.4×2.1×2.5 |

| WNS2-1.25-Y(Q) | 2 | 1.25 | 194 | 4.4×2.1×2.5 |

| WNS3-1.0-Y(Q) | 3 | 1 | 184 | 4.6×2.3×2.6 |

| WNS3-1.25-Y(Q) | 3 | 1.25 | 194 | 4.6×2.3×2.6 |

| WNS4-1.25-Y(Q) | 4 | 1.25 | 194 | 4.7×2.5×2.9 |

| WNS4-1.6-Y(Q) | 4 | 1.6 | 204 | 4.7×2.5×2.9 |

| WNS5-1.25-Y(Q) | 5 | 1.25 | 194 | 5.3×2.7×3.3 |

| WNS5-1.6-Y(Q) | 5 | 1.6 | 204 | 5.3×2.7×3.3 |

| WNS6-1.25-Y(Q) | 6 | 1.25 | 194 | 5.9×2.6×3.0 |

| WNS6-1.6-Y(Q) | 6 | 1.6 | 204 | 5.9×2.6×3.0 |

| WNS8-1.25-Y(Q) | 8 | 1.25 | 194 | 5.9×2.8×3.1 |

| WNS8-1.6-Y(Q) | 8 | 1.6 | 204 | 5.9×2.8×3.1 |

| WNS10-1.25-Y(Q) | 10 | 1.25 | 194 | 7.7×2.8×3.1 |

| WNS10-1.6-Y(Q) | 10 | 1.6 | 204 | 7.7×2.8×3.1 |

| WNS15-1.25-Y(Q) | 15 | 1.25 | 194 | 7.0×3.1×3.6 |

| WNS15-1.6-Y(Q) | 15 | 1.6 | 204 | 7.0×3.1×3.6 |

| WNS20-1.25-Y(Q) | 20 | 1.25 | 194 | 8.3×3.4×4.0 |

| WNS20-1.6-Y(Q) | 20 | 1.6 | 204 | 8.3×3.4×4.0 |

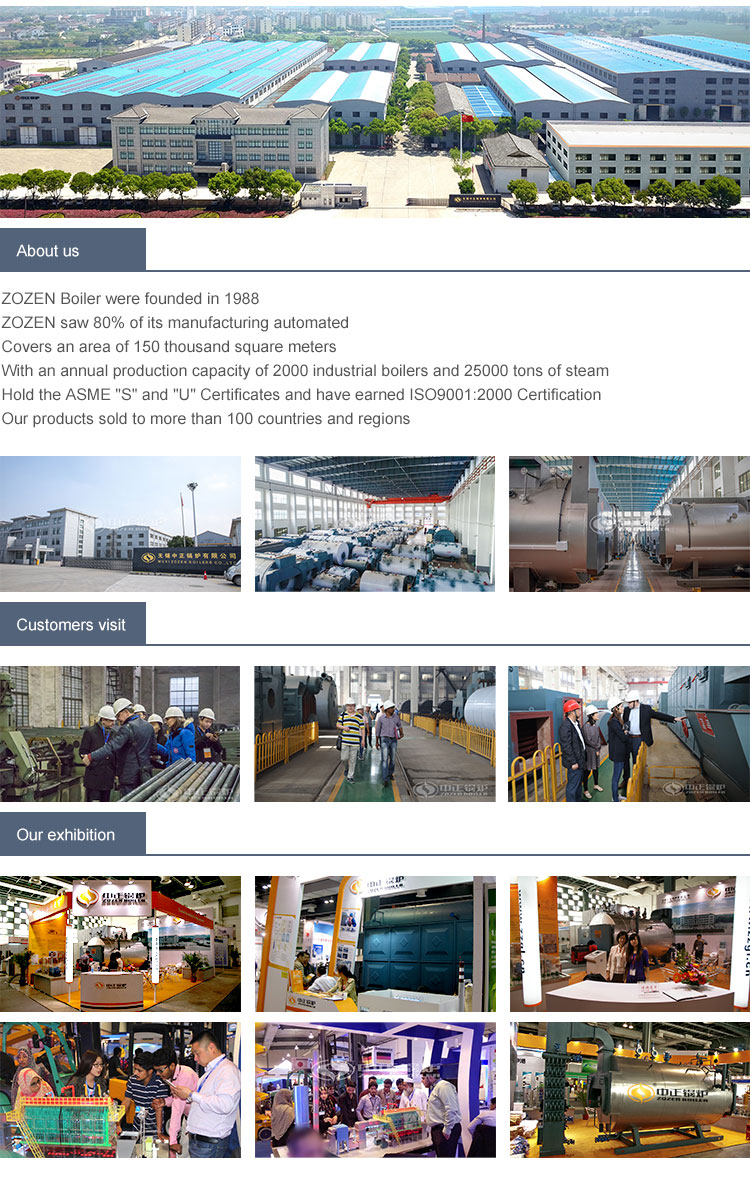

ZOZEN Factory

ZOZEN is one of the best modern boiler manufacturers in China, our products include steam boilers, hot water boilers and thermal oil heaters. ZOZEN boiler is located in Wuxi, covers 150 thousand square meters of production area, equipped with first-class production equipment, passed the ISO9001:2000 international quality system certification. The company gained the ” S ” and ” U ” steel seal from ASME of US.

Pre-sale service:

-

- We help customer choose the best boiler model according to different requirements of various industry. Before delivery we will provide foundation drawing, layout drawing, boiler room layout, etc.

In-sale service:

-

- We keep 24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

- provide full range of original spare parts.

- Engineers abroad installation and commissioning service is available.

- Our engineers will held a training for boiler workers to ensure the safe operation.

- Free maintenance and repair for one year and lifelong service.