SZS series gas boiler adopt the international popular shell type three returns, all wet back structure, large volume design of combustion chamber, so that the combustion is more sufficient.

The fuel burns under slightly positive pressure in the furnace. The high temperature flue gas enters the first flue tube bundle backwards along the furnace through the backcombustion chamber at a turning point of 180°, and then enters the second tube bundle through the compression front flue box at a turning point of 180°. After convection heat transfer, it enters the atmosphere.

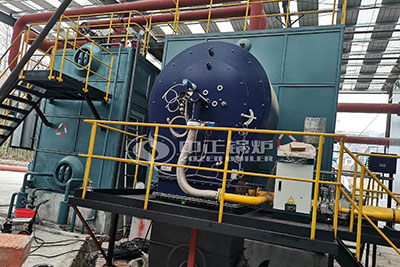

SZS series gas boiler

This boiler body combustion chamber adopts the full corrugated furnace structure, which effectively increases the radiation heat transfer area and improves the thermal efficiency of the boiler. At the same time, the stiffness of the furnace also increases, which effectively weakens the expansion stress of the furnace. The thermal efficiency is improved while the fuel can be fully burned in the furnace, saving fuel costs for the user.

SZS series gas boiler has the advantages of full combustion, pollution-free emission, convenient operation and convenient installation. Boiler has high thermal efficiency, large output, strong load adaptability, high degree of automation, convenient operation, safe and reliable operation. It is an ideal green environmental protection product with high efficiency, low consumption and low pollution. The assembled water tube boiler is composed of upper and lower drum, membrane water wall, convection tube bundle, energy saving device and condenser. After the fuel is burned in the furnace, the flue gas is discharged into the chimney through the convection tube bundle and flue gas waste heat recovery device.

gas fireds steam boilers

Gas boiler dealer – ZOZEN production base has realized 80% of the automatic production process. The furnace plate adopts the advanced technology of pre-expansion and then full welding, and then expansion, which not only prevents the corrosion of pipe gap, but also enhances the welding strength. The screw pipe with high heat transfer coefficient is used to strengthen the heat transfer effect of convection, reduce the exhaust temperature and improve the thermal efficiency of the boiler. In the process of digital production, each process is precisely controlled by computer, so that the boiler quality is guaranteed. As the quality and safety of industrial special equipment, the boiler is also the most important, and users can rest assured that it can be used.