The WNS series gas fired steam boilers produced by ZOZEN is a hot-selling furnace type and is widely used in the production of various industries. WNS series boilers are based on advanced design experience at home and abroad, optimized the overall boiler structure, sufficient steam storage space and heating surface, so that the boiler can efficiently produce higher thermal power and high-quality steam. This type of boiler has the characteristics of safety, reliability, high efficiency, energy saving and environmental protection, convenient maintenance, durable, automatic intelligent control, etc.

The 10 ton gas steam boilers adopt high-standard design, and the whole set of equipment including the main body, auxiliary machinery and accessories are made of high-quality materials to ensure 100% safe operation and long-term stable operation throughout the year. The design of the furnace is small, compact and concise, easy to install, and easy to transport. The use of international brand burners further improves the stability of combustion and makes the fuel burn better.

wns gas fired boiler price

The low pressure gas steam boiler adopts the original imported burner, fully automatic programming control, automatic fan blowing, electronic automatic ignition, automatic oil and gas combustion, automatic ratio adjustment of air and oil (gas), good atomization effect, full combustion, low NOX, energy saving and environmental protection . Under normal circumstances, when the boiler steam pressure reaches the set value, the burner automatically stops burning, and when the steam pressure is lower than the set value, the burner automatically starts to work. When there is abnormal fuel or air intake, the fault light will be on, the program control device will immediately stop the fuel output, and the burner will automatically stop.

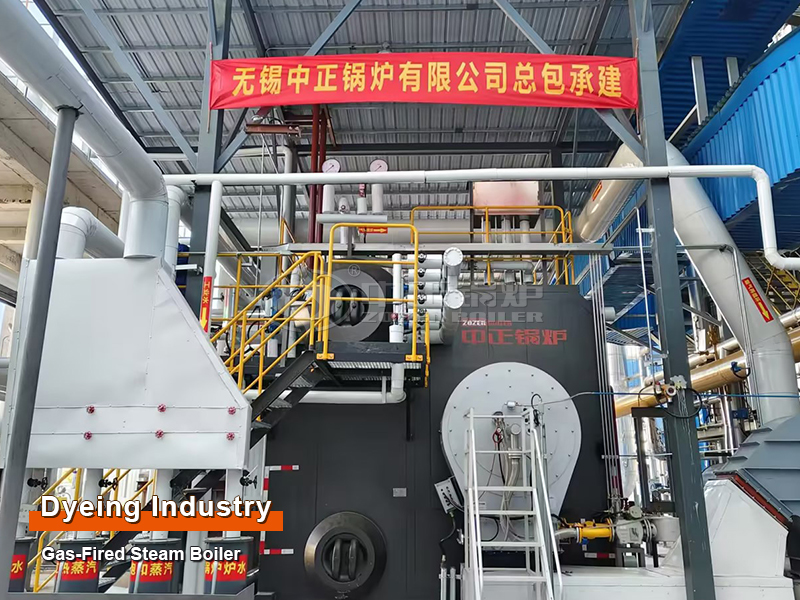

ZOZEN Boiler designed the boiler plan for the customer, which is two WNS series 10-ton natural gas-fired steam boilers. This series of boilers use full corrugated furnace to enhance flue gas disturbance and effectively improve the heat transfer effect. At the same time, it is matched with the high-efficiency heat transfer element threaded flue tube designed and developed by ZOZEN, so that the boiler can effectively produce higher thermal efficiency and high-quality steam, satisfying customers Production needs.

WNS gas steam boiler

ZOZEN WNS series gas boilers can choose a variety of energy-saving devices and condensers. By reducing the exhaust gas temperature and increasing the boiler inlet water temperature to achieve the effect of improving thermal efficiency, the thermal efficiency of the boiler can be increased to more than 98%, thereby saving energy consumption and helping enterprises Reduce boiler operating costs.

In addition, ZOZEN boilers can also use advanced low-nitrogen burners to ensure that the fuel is fully burned, while effectively inhibiting the formation of nitrogen oxides, reducing NOx emissions, and easily helping companies meet the environmental protection requirements of green production. The customer is very satisfied with the operation of this gas-fired steam boiler and provides sufficient high-quality steam for the production of the enterprise. At the same time, the automatic boiler control system helps companies operate and run the boiler more safely. Welcome to consult!