Part 1: Characteristics of Industrial food boiler

Industrial food boiler play a crucial role in the food processing sector, ensuring efficient heat generation for various applications. These specialized boilers are designed to meet stringent safety and quality standards, catering specifically to the unique requirements of the food industry. With features like high thermal efficiency, advanced control systems, and eco-friendly operations, industrial food boiler are indispensable in maintaining product quality and safety.

Part 2: ZOZEN’s Industrial Food Boiler Overview

ZOZEN, a leading provider of boiler technologies, offers a range of industrial food boiler that are tailored to meet the demands of the food processing industry. Let’s delve into three industrial food boiler:

The WNS series gas-fired (oil-fired) steam boiler offers a thermal capacity of 1-20 t/h and ensures fully automatic safe operation with features like Boiler IoT, remote control, and expert management. With a remarkable thermal efficiency of ≥98%, this industrial food boiler incorporates a corrugated furnace and threaded smoke tube design, along with an economizer and condenser for optimal performance. Its advanced control system allows for unattended operation, facilitating easy maintenance. Eco-efficient operations are ensured through a low-nitrogen burner and combustion technology, keeping NOx emissions ≤30mg/Nm³.

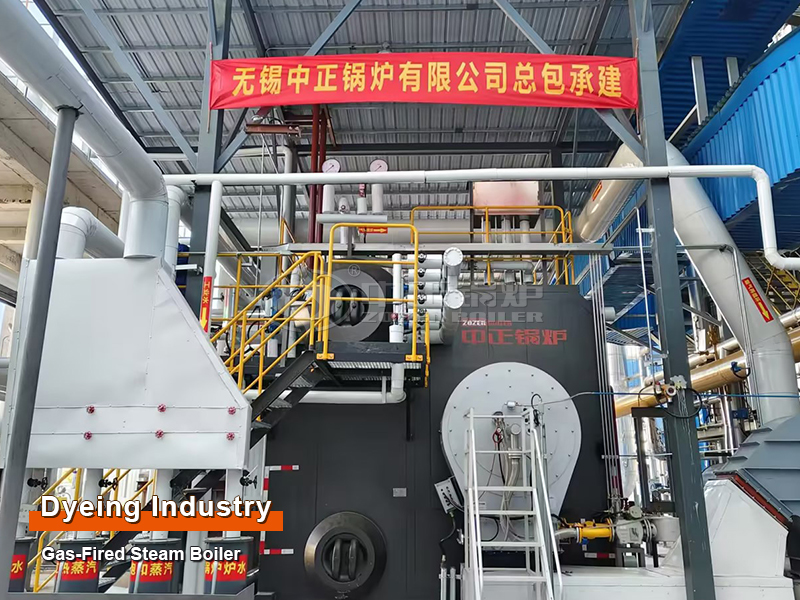

ZOZEN industrial food boiler

The SZS series gas-fired (oil-fired) steam boiler boasts a thermal capacity of 2-110 t/h, features a double drums, longitudinal arrangement, and “D” type chamber structure. With a thermal efficiency of ≥98%, this boiler is designed with a water-cooled wall and large furnace, complemented by an economizer that reduces exhaust temperature for enhanced efficiency. Similar to the WNS series, the SZS boiler features an advanced control system for unattended operation, making maintenance hassle-free. the system prioritizes eco-efficiency by employing cutting-edge low-nitrogen burner technology and advanced combustion methods. These innovations effectively keep NOx emissions well below the stringent threshold of 30mg/Nm³.

The YQW series gas-fired horizontal thermal oil heater boasts a thermal capacity ranging from 1400 kW to 14000 kW and features an advanced control system. This system ensures precise regulation of oil temperature and pressure, guaranteeing a secure operational environment. With fully automatic safe operation, the heater enables effortless maintenance and unattended running, enhancing operational ease. Its simple operation is facilitated by packaged delivery, reducing installation time. Environmentally conscious, the heater is eco-efficient, with low-nitrogen burner emissions ≤30mg/Nm³, aligning with sustainable practices while maintaining high performance in industrial heating applications.

Case : Yili Group’s Partnership with ZOZEN Boiler

In the ever-evolving beverage industry, equipment choice is vital for product quality. Yili Group, a global food company, upholds strict standards in production line selection. ZOZEN Boiler supports Yili’s bottled water subsidiary, Antu Yili. Yili purchased WNS series gas-fired steam boilers in 2019, delivering exceptional performance. Recent inspections confirm the boilers’ excellent condition. This collaboration underscores ZOZEN’s reliability and Yili’s trust in their partnership.

ZOZEN’s Strength and Service System:

ZOZEN Boiler’s commitment to excellence in both product quality and customer service sets them apart in the industry. With a focus on innovation, reliability, and customer satisfaction, ZOZEN continues to be a preferred choice for industrial food boiler, providing cutting-edge solutions tailored to meet the specific needs of food processing facilities. Trust ZOZEN for top-tier industrial food boiler that elevate efficiency and quality standards in the food industry.