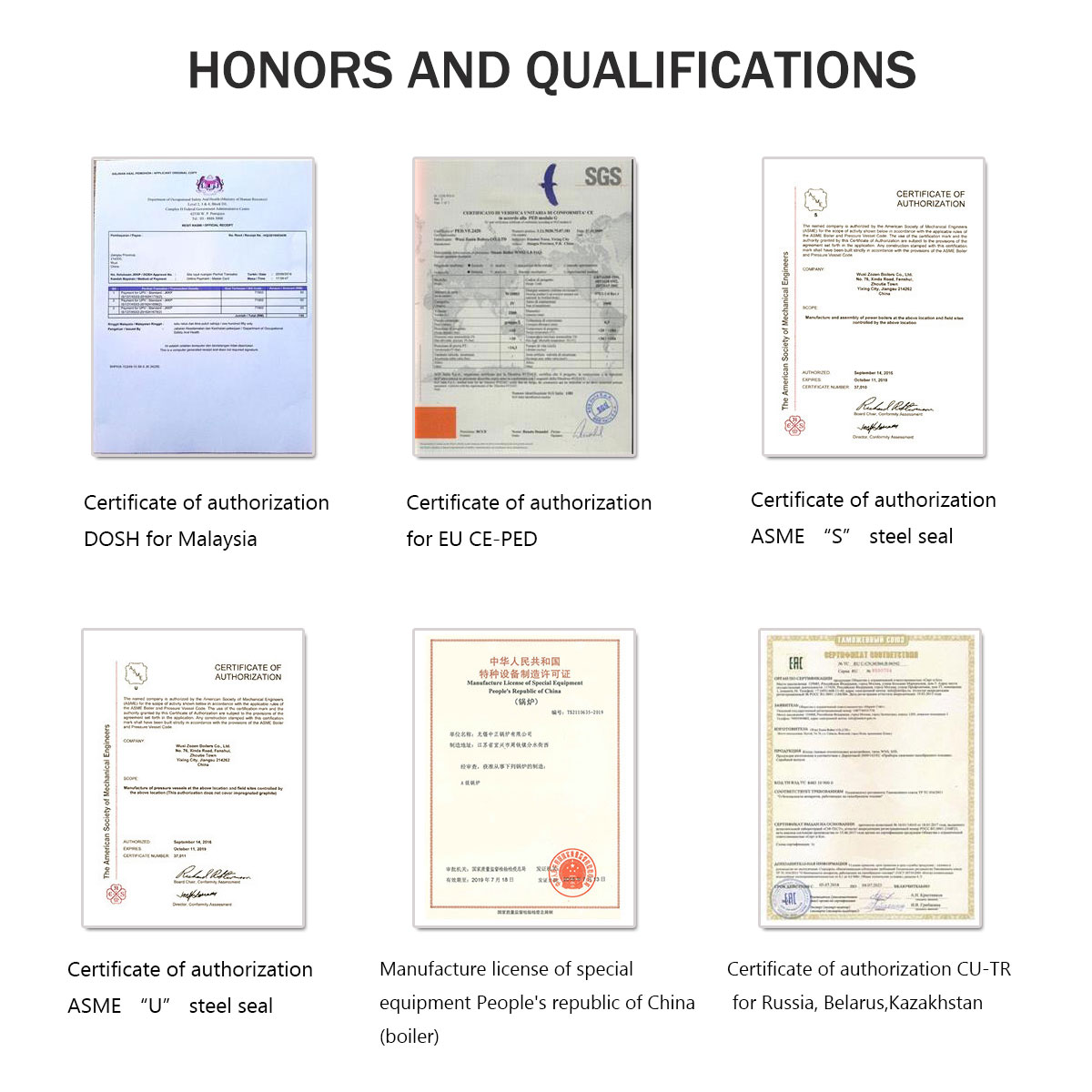

Pressure: 0.7 – 1.25 Mpa

Temperature: 115 / 70, 95 / 70 ℃

Fuel: Bituminous Coal,Lean Coal,Anthracite

Industries: Heating, Hotels, Schools, Hospitals

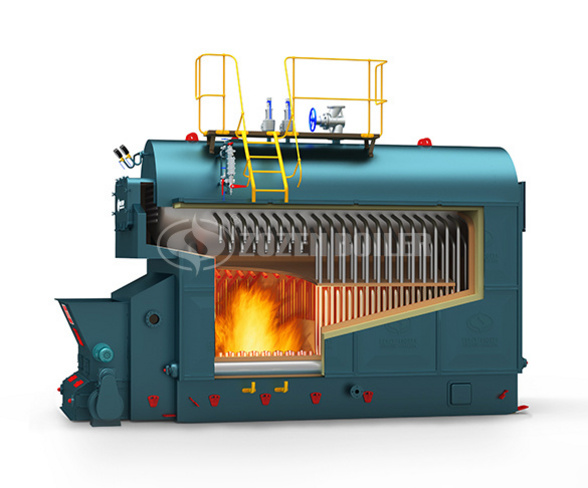

DZL coal-fired hot water boiler refers to the industrial boiler fueled by coal, mainly used for heating hot water. Coal-fired horizontal hot water boiler consists of furnace shell, furnace chamber, firework passage and water intercalation. The furnace chamber is located at the lower part of the furnace shell, and the lower end of the firework passage is connected with the upper end of the furnace chamber. The upper and lower parts of the furnace shell are respectively provided with a water outlet and a water return outlet, a furnace outlet is provided on one side of the furnace shell in the middle of the corresponding furnace chamber, and a smoke outlet is provided on the top of the furnace shell.

Easy Maintenance

Horizontal coal-fired atmospheric pressure hot water boiler, the upper is equipped with enough manhole, personnel can enter the furnace body from the manhole, greatly facilitate the inspection and maintenance of the boiler.

Wide Applicability

DZL coal-fired industrial hot water boiler is widely used in factories, hotels, hospitals, office buildings, schools, bath centers, baths and other enterprises and institutions, to meet the use of the unit bath, domestic hot water and heating requirements.

Environmental Protection and Energy Saving

Horizontal coal-fired hot water boiler belongs to the vertical type of single boiler barrel in structure. Water wall pipes are installed on the left and right sides of the furnace, and wing flue is formed. Threaded smoke pipes are arranged in the boiler barrel.

After the fuel in the combustion, the flame through the low wall to the combustion chamber, the state from the combustion chamber state through two flanks form before flue to smoke box, again by smoke tube bundle to the smoke chamber, then northwards by induced draft fan through the chimney discharged into the atmosphere, not only can prevent the at the bottom of the pot shell from furnace heat radiation, and can make high temperature smoke tube plate inlet temperature drops, and supplemented by water ejector, no dead zone at the bottom of the drum, also can effectively prevent the tube plate because too cold, boiling and scaling and furnace bottom convex hull, smoke to the smoke chamber can dust removal effect, also reduces the original exhaust dust concentration.

Low Cost

Horizontal coal-fired atmospheric pressure hot water boiler, the use of a single boiler tube longitudinal layout of the three-return fire-water tube structure, both sides of the furnace covered with light tube water-cooling wall tube, the design structure is reasonable and compact;The heating area is large, the flue gas flow is long, the heat transfer effect is good, the exhaust temperature is low, so the thermal efficiency is high, the operation cost is low, the use is more economical.

The boiler body is compact in layout, occupies a small area, convenient in transportation, adopts quick delivery, short installation period, low installation cost, less user investment, quick recovery benefit.