Brand Name: ZOZEN Boiler Co., Ltd.

Certification: ISO, CE, ASME

Model Number: SZL series

Minimum Order Quantity: 1 set

Price: Contact Us for Latest Price

Payment Terms: L/C, T/T

E-mail us: zhulin@zozen.com

WhatsApp:+86 18861589035

Detail Information

- Output: Steam

- Fuel Design: Biomass molding granules, wood chip, corn cob, saw dust, palm shells, rice husk, etc.

- Steam Capacity: 6 ton, 20 ton, 25 ton, 30 ton, 35 ton

- Working Pressure: 1.25 MPa, 1.6 MPa, 2.5 MPa

- Rated Steam Temperature: 194℃, 204℃, 225℃

- Warranty: 1 Year

- Structure: horizontal type boiler

- Application: Heating, chemical, food, tobacco, textile, print and dyeing, feed, medicine, building materials, wine, hospital

- Design Efficiency: High Effciency 86%

SZL series biomass-fired steam boiler Description

The SZL series biomass-fired boiler is a chain grate water tube boiler designed by ZOZEN Boiler based on advanced international technology and experience. It features a horizontal double-drum and vertical layout structure. The boiler consists of two major parts: the upper part is the heating surface and the lower part is the combustion equipment. The front of the boiler body is surrounded by water-cooled walls. The upper part is connected with drum and the lower part is connected with the header to form the combustion chamber, absorbing the radiation heat of the furnace. At the rear end, a convection tube bundle is arranged between the upper and lower drums. After the fuel is burned in the furnace, the high-temperature flue gas is swept across the convection tube bundle for the secondary return, then guided to a separately arranged economizer and finally enters the dust collector before being discharged through the chimney.

SZL series biomass-fired steam boiler More Details

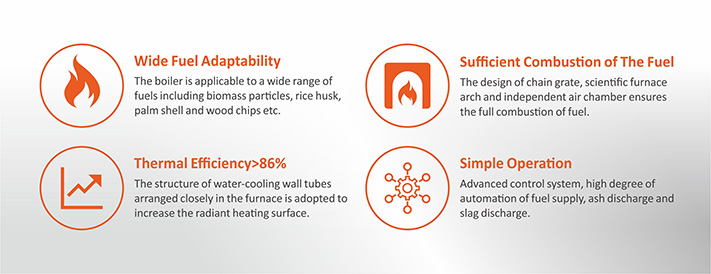

SZL series biomass-fired steam boiler Advantages

Product Parameters

| Model | Steam

Capacity |

Steam

Pressure |

Steam

Temperature |

Shipping

Dimension |

Heat

Efficiency |

| SZL6-1.25-SCⅢ | 6 t/h | 1.25 Mpa | 194 ºC | 6.20×2.80×3.65

7.20×2.60×2.80(m) |

>83% |

| SZL6-1.6-SCⅢ | 6 t/h | 1.6 Mpa | 204 ºC |

6.20×2.80×3.65 7.20×2.60×2.80(m) |

>83% |

| SZL6-2.5-SCⅢ | 6 t/h | 2.5 Mpa | 225 ºC |

6.20×2.80×3.65 7.20×2.60×2.80(m) |

>83% |

| SZL8-1.25-SCⅢ | 8 t/h | 1.25 Mpa | 194 ºC | 7.10×3.52×3.65

7.80×3.10×2.80(m) |

>83% |

| SZL8-1.6-SCⅢ | 8 t/h | 1.6 Mpa | 204 ºC |

7.10×3.52×3.65 7.80×3.10×2.80(m) |

>83% |

| SZL8-2.5-SCⅢ | 8 t/h | 2.5 Mpa | 225 ºC | 7.10×3.52×3.65

7.80×3.10×2.80(m) |

>83% |

| SZL10-1.25-SCⅢ | 10 t/h | 1.25 Mpa | 194 ºC | 7.90×3.52×3.65

8.40×3.10×2.80(m) |

>83% |

| SZL10-1.6-SCⅢ | 10 t/h | 1.6 Mpa | 204 ºC |

7.90×3.52×3.65 8.40×3.10×2.80(m) |

>83% |

| SZL10-2.5-SCⅢ | 10 t/h | 2.5 Mpa | 225 ºC |

7.90×3.52×3.65 8.40×3.10×2.80(m) |

>83% |

| SZL12-1.25-SCⅢ | 12 t/h | 1.25 Mpa | 194 ºC | 8.80×3.52×3.65

8.40×3.10×2.80(m) |

>86% |

| SZL12-1.6-SCⅢ | 12 t/h | 1.6 Mpa | 204 ºC |

8.80×3.52×3.65 8.40×3.10×2.80(m) |

>86% |

| SZL12-2.5-SCⅢ | 12 t/h | 2.5 Mpa | 225 ºC |

8.80×3.52×3.65 8.40×3.10×2.80(m) |

>86% |

| SZL15-1.25-SCⅢ | 15 t/h | 1.25 Mpa | 194 ºC | 9.60×3.20×3.65

8.30×3.30×3.00(m) |

>86% |

| SZL15-1.6-SCⅢ | 15 t/h | 1.6 Mpa | 204 ºC |

9.60×3.20×3.65 8.30×3.30×3.00(m) |

>86% |

| SZL15-2.5-SCⅢ | 15 t/h | 2.5 Mpa | 225 ºC |

9.60×3.20×3.65 8.30×3.30×3.00(m) |

>86% |

| SZL20-1.25-SCⅢ | 20 t/h | 1.25 Mpa | 194 ºC |

10.65×3.28×3.60 9.30×3.81×2.80(m) |

>86% |

| SZL20-1.6-SCⅢ | 20 t/h | 1.6 Mpa | 204 ºC |

10.65×3.28×3.60 9.30×3.81×2.80(m) |

>86% |

| SZL20-2.5-SCⅢ | 20 t/h | 2.5 Mpa | 225 ºC |

10.65×3.28×3.60 9.30×3.81×2.80(m) |

>86% |

| SZL25-1.25-SCⅢ | 25 t/h | 1.25 Mpa | 194 ºC | 11.65×3.80×3.60

9.30×3.81×3.00(m) |

>86% |

| SZL25-1.6-SCⅢ | 25 t/h | 1.6 Mpa | 204 ºC |

11.65×3.80×3.60 9.30×3.81×3.00(m) |

>86% |

| SZL25-2.5-SCⅢ | 25 t/h | 2.5 Mpa | 225 ºC |

11.65×3.80×3.60 9.30×3.81×3.00(m) |

>86% |

| SZL30-1.25-SCⅢ | 30 t/h | 1.25 Mpa | 194 ºC | 10.00×3.36×3.60(m) | >86% |

| SZL30-1.6-SCⅢ | 30 t/h | 1.6 Mpa | 204 ºC | 10.00×3.36×3.60(m) | >86% |

| SZL30-2.5-SCⅢ | 30 t/h | 2.5 Mpa | 225 ºC | 10.00×3.36×3.60(m) | >86% |

| SZL35-1.25-SCⅢ | 35 t/h | 1.25 Mpa | 194 ºC | 10.00×3.65×3.85(m) | >86% |

| SZL35-1.6-SCⅢ | 35 t/h | 1.6 Mpa | 204 ºC | 10.00×3.65×3.85(m) | >86% |

| SZL35-2.5-SCⅢ | 35 t/h | 2.5 Mpa | 225 ºC | 10.00×3.65×3.85(m) | >86% |

ZOZEN Factory

ZOZEN is one of the best modern boiler manufacturers in China, our products include steam boilers, hot water boilers and thermal oil heaters. ZOZEN boiler is located in Wuxi, covers 150 thousand square meters of production area, equipped with first-class production equipment, passed the ISO9001:2015 international quality system certification. The company gained the “S” and “U” steel seal from ASME of US.

Pre-sale service:

- We help customer choose the best boiler model according to different requirements of various industry. Before delivery we will provide foundation drawing, layout drawing, boiler room layout, etc.

In-sale service:

- We keep 24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

- provide full range of original spare parts.

- Engineers abroad installation and commissioning service is available.

- Our engineers will held a training for boiler workers to ensure the safe operation.

- Free maintenance and repair for one year and lifelong service.