The two pass gas fired boiler structure greatly improves the combustion efficiency and thermal efficiency of the gas boiler. The fuel is burned in the furnace bile under slight positive pressure, and the high-temperature flue gas is turned 180° into the first flue bundle along the furnace bile backward through the re-combustion chamber, and then turned 180° into the second bundle through the pressurized front flue box, which is discharged into the atmosphere after convection heat exchange.

The advantage of wet back gas fired boiler is that the combustion chamber behind the furnace is soaked in water wet-back combustion chamber, there is no trouble of burning, it is because the wet-back combustion chamber is soaked in the water surroundings, but also to improve the radiation heat transfer area and heat transfer efficiency of the boiler, this structure is very popular in the international.

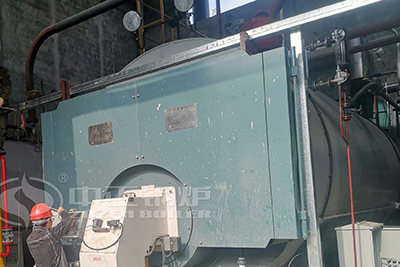

2000kg gas fired steam boiler

ZOZEN’s WNS2-1.0-Y.Q model 2 ton capacity gas boiler is a highly automated horizontal fire tube boiler, equipped with complete automatic control devices and safety protection devices, to achieve automatic water level control and critical low water level alarm and furnace stop; automatic steam pressure control and overpressure alarm; automatic ignition of the boiler, automatic adjustment of burner fire and flame out protection to ensure the safety of the boiler The boiler automatic ignition, burner fire automatic regulation and flame out protection, to ensure the safety of boiler operation.

Two pass gas boiler, flame in the large combustion chamber micro positive pressure combustion, fully extended, low combustion heat load, high combustion thermal efficiency, effectively reduce the exhaust temperature, energy saving and consumption reduction, the use of economic. The structure of corrugated furnace liner and threaded flue pipe improves the heat absorption strength of the boiler and meets the need of heat expansion of the heat exchange surface, which is scientific and reasonable and durable.

wet back fire tube boiler

The 2000kg gas-fired boiler with compact structure, safety and reliability, easy operation, rapid installation, low pollution, low noise, high efficiency, etc., is widely used in various industries for production steam and domestic and heating steam. The boiler body of WNS series gas-fired steam boiler is manufactured in the factory, and the piping, valves and instruments are installed randomly, so that the boiler can be put into trial operation after it is delivered to the project site and connected to the gas source, power supply and water pipeline, which greatly shortens the installation period and ensures the quality of products.

As an industrial boiler manufacturer with more than 30 years of manufacturing and sales experience, ZOZEN is fully qualified, has advanced processing technology and strict quality control, which effectively guarantees the quality of each boiler. In the past 10 years, there are 15580 successful cases in the chemical industry, textile industry, packaging industry, food industry, etc. If you also need environmental protection, energy saving and high efficiency industrial steam boilers, please feel free to contact us.