As an essential heating equipment in the production of chemical enterprises, boilers affect the production efficiency and long-term development of enterprises, so great attention is paid to the quality and long-term operation effect of boiler products in the procurement process of industrial boiler machine. ZOZEN Boiler is a professional industrial boiler design, manufacturing and service company, with advanced production equipment and professional technology, after-sales guarantee and other comprehensive capabilities, has become a boiler supplier for many large industrial enterprises.

Recently, a large state-owned modern phosphate open pit mining and phosphorus chemical company, in order to actively and fiercely compete in the market, needs to upgrade its industry, develop fine chemicals, pharmaceutical intermediates and pesticide intermediates, and build a technology development project with an annual capacity of 1,500 tons of chemical products. Among them, key processes such as fluorination and distillation on fluoronitrobenzene production need to use high quality steam as heat source. In order to improve production quality and efficiency, the chemical plant must ensure a stable supply of steam and meet environmental emission standards, so it needs to purchase a set of stable operation and environmentally friendly steam boiler system.

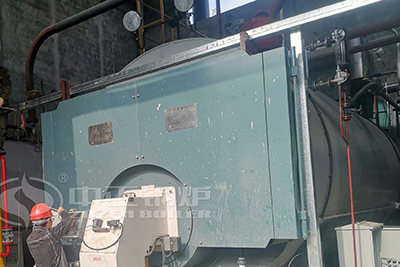

The installed ZOZEN 4 tph gas steam boiler

After understanding the specific needs of the chemical plant, the ZOZEN boiler design team conducted an in-depth understanding of the actual production process of the chemical plant, and held several technical discussions with the person in charge of the chemical plant. Finally, ZOZEN Boiler designed the energy-saving and environment-friendly WNS series gas steam boiler system solution, which became the boiler equipment supplier for the new project of the chemical plant with its reliable quality and energy-saving and environment-friendly technology.

Based on the actual heat demand of the processing line, ZOZEN Boiler recommends the WNS series internal combustion horizontal gas boiler, which produces 4 tons of steam per hour at a pressure of 1.25mpa. This natural gas steam boiler has highly efficient heat transfer components such as large diameter corrugated hearth and threaded flue pipe, and sufficient steam storage space and heating surface, making the boiler’s output sufficient and stable. At the same time, the boiler also adopts a low-NOx combustion system to reduce the generation of nitrogen oxides at source, easily achieving the environmental protection standard of no more than 100mg/Nm³ of nitrogen oxides.

The WNS series 4 ton steam boiler is a two-way quick installation boiler, which can be installed as a whole at the boiler factory and delivered to the project site for commissioning and production use after a simple installation, effectively shortening the boiler installation time and infrastructure costs. Surprisingly, the high thermal efficiency of the gas boiler significantly saves gas fuel, which is a typical environmentally friendly boiler product.

ZOZEN condensing gas fired boiler

At the same time, the steam used in this project is all indirectly heated in the unit without contacting the material, so the steam condensate produced after heat exchange is clean water, which can be completely used twice, and the direct accumulation enters the boiler system for reuse to produce steam. ZOZEN technicians added a condensate recovery system to this 4 ton steam boiler in order to achieve the process demand of using condensate directly, so that steam condensate can be effectively used. ZOZEN always stands for the customer’s perspective to solve problems and provide customers with industrial boiler systems suitable for actual production characteristics, please feel free to contact us for more details.