The traditional classic design is a three-pass design. The flame and high-temperature flue gas emitted from the burner flow from the front of the furnace to the rear to form the first return: the high-temperature flue gas flows from the reburning chamber to the smoke box through the second return smoke tube Second return stroke: Finally, the third return stroke is formed by the flue gas flowing from the front smoke box to the rear boiler flue gas outlet through the third return stroke. The use of corrugated furnace liner effectively increases the heat exchange area and enhances turbulent heat transfer. At the same time, it can alleviate the possible shortening of equipment life caused by thermal expansion and contraction, and greatly extend the service life of equipment. The wet back design increases heat transfer to avoid the hidden danger of the rear smoke box burning out.

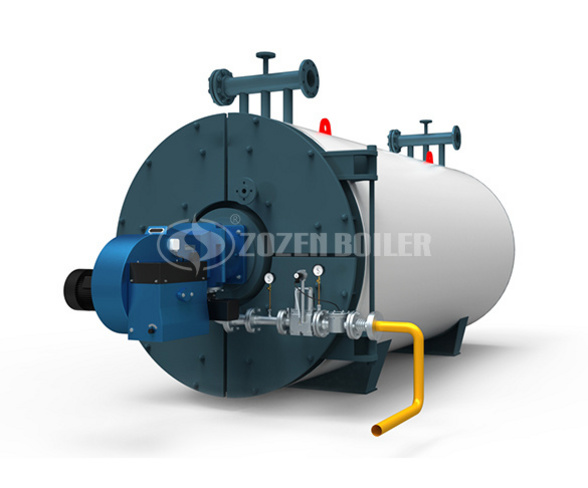

Fulton’s newly launched FB S-type boiler, on the basis of preserving traditional classic advantages, adhering to the wisdom and experience of a large number of professional engineers from the United States, Britain, and China Fulton Corporation, combined with China’s specific use, carried out Design and perfection, ample heating area, abundant water volume, unique front and rear smoke box manufacturing process, integrated design of water level gauge and boiler body, integrated design of boiler and burner, and advanced automatic control functions Give it a unique new connotation.

The heating area of the boiler is an important indicator to check the thermal efficiency of the boiler. If the heating surface is sufficient, the heat transfer is sufficient. The boiler has high efficiency, the Fulton FB-S boiler has sufficient heating area, and the average heat absorption per unit area is small, the heat transfer is sufficient, and the boiler operates stably under load changes to ensure continuous high-efficiency combustion.

In order to ensure the safe operation of the boiler and to improve the quality of the steam, the design of the FB-S boiler considers the sufficient water volume. The furnace liner is arranged at a low position to retain a large water level safety range and a large steam evaporation surface. The steam moisture content is low.

The integrated water level gauge and boiler body are used as a component to measure the water level in the drum. They play an extremely important role in the safe operation of the boiler. Fulton boiler adopts the integrated design of the water level gauge and the boiler body. The model is more compact and beautiful, and it can avoid the harm to people and equipment caused by other types of water level gauges due to false water levels.

The integrated design of the boiler and the burner the design of the Fulton burner and the boiler body fully considers the consistency of the burner and the body. The burner and the boiler are organically combined to achieve the best combustion ratio and reduce the harmful gas. Emissions, further increase environmental protection and improve boiler thermal efficiency.

According to the characteristics of the boiler as a pressure vessel, the Fulton FB-S boiler is equipped with high reliability, fully automatic microcomputer program controller with high degree of automation and easy operation. Only one button is needed to start and stop the boiler. During the start and stop process, the program controller strictly monitors the fuel system, the air supply system and the flame detection system, implements automatic flameout protection, and prompts the furnace worker, when the load changes, the control system can automatically adjust the fuel ratio to ensure full and complete combustion. The reserved data output interface is more convenient for users to connect with central control systems such as building control to meet the needs of users with high requirements for automatic control.