As a coal fired boiler manufacturer with more than 30 years of design and manufacturing experience, we can produce chain grate boilers and circulating fluidized bed boilers with a capacity of 2-100 tons. This series of boilers are mainly used in chemical, food, packaging, building materials, rubber and other industrial production. However, as different countries have different standards for environmental protection, local environmental protection standards must be confirmed before purchasing boilers. It is sold in Bangladesh, Pakistan, Malaysia, Thailand, UK, Philippines, Ukraine and other countries.

coal fired hot water boiler

The chain grate boiler and circulating fluidized bed boiler manufactured by ZOZEN include SZL series double boiler tube vertical boiler, DZL series single boiler tube vertical boiler, SHX series and DHX series circulating fluidized bed boiler, DHL series Angle tube chain grate boiler and SHL series double boiler tube bulk chain grate boiler, etc. 6 different models. They have a wide range of fuel applicability, can be applied to bituminous coal, anthracite, lean coal, lignite and other kinds of coal; Equipped with a reasonable air regulating device to achieve accurate air distribution effectively improve combustion efficiency.

DZL type boiler has the advantages of fast installation, time-saving and material saving, compact structure, small floor area, high reliability, and high thermal efficiency and strong overload capacity, etc., and it is the best design product for domestic similar products. DZL series adopts light chain grate with high degree of automation, equipped with dust removal equipment, less environmental pollution, has a good comprehensive economic and technical indicators, well received by the majority of consumers.

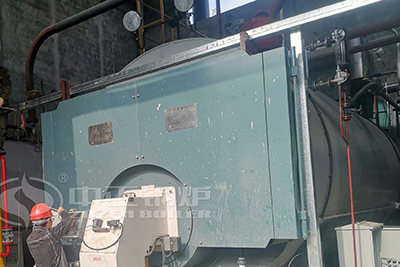

coal fired boiler manufacturer

Product Features

- Boiler type is horizontal three-return water and fire tube boiler. The boiler heat exchange system is composed of the boiler barrel, the left and right sets, and the water cooling wall. The main heating surface has the water cooling wall of the furnace, part of the boiler barrel and the convection tube bundle in the boiler barrel.

- Advanced design performance. The main heating surface tube of the boiler is made of seamless steel tube for low and medium pressure boiler, the boiler barrel is made of special steel plate for boiler, and the left and right sets are made of seamless steel tube.

- The boiler arch is made of fire-resistant concrete. The rear arch is low and long, so it burns well. The wings of the flue and the side wall tiles are made of refractory sintered bricks. Boiler front wall and back wall adopt universal firebrick.

- Reasonable exhaust ventilation, large combustion chamber and strong applicability of coal. Suitable for all kinds of bituminous coal or anthracite, mixed coal, well burned.

- The high-temperature flue gas first enters the settlement chamber, and then enters the two wings of flue and front smoke box from both sides, so the effect of smoke elimination and dust removal is good.

- Simple water circulation, reasonable structure of pressurized parts, and safe operation under the condition of ensuring water quality.

Wuxi ZOZEN Boiler Company as a coal fired boiler manufacturer that founded in 1988 has been focusing on the research, development and production of industrial boilers for over 30 years. Oil-fired and gas-fired boilers are our most technologically mature products, with a thermal efficiency of up to 98%, saving users a lot of use costs. Our boiler products cover more than 100 countries and regions in the world, so far there are 13350 successful cases, welcome to visit our factory!