The new gas-fired steam boiler with 24 tons steam per hour provided by ZOZEN for various industries is SZS model, which is a water tube boiler of D-type structure, it consists of upper and lower pot, membrane water cooling wall, convection tube bundle and energy saver and condenser, after the fuel is burned in the furnace, the flue gas is discharged into the chimney through the convection tube bundle and flue gas waste heat recovery device. The SZS gas boiler is a horizontal gas boiler with excellent performance and powerful output, which can fully meet the use of food factories, beverage factories, leather factories, garment factories, printing and dyeing factories, pharmaceutical factories, metallurgical factories, etc. The SZS gas boiler is also a representative work of environmental protection and energy saving, with more than 95% combustion efficiency and almost no sulfide and dust emission, which is the most popular boiler at present.

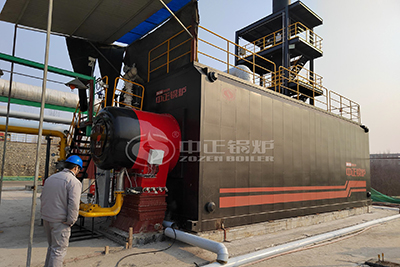

gas steam boiler in chemical plant project

The 24tph steam boiler adopts the internationally popular pot shell type three-return, full wet-back structure and large volume design of the combustion chamber, which makes the combustion more adequate. The boiler adopts the advanced technology of pre-expansion and then full welding, followed by re-expansion, which not only prevents tube gap corrosion, but also enhances welding strength. The threaded flue pipe with high heat transfer coefficient strengthens the convection heat transfer effect, reduces the exhaust temperature and improves the thermal efficiency of the boiler.

The case of biogas steam boiler for food industry, Jiahua Biotechnology Co., Ltd. cooperated with ZOZEN Boiler to sign a contract for a superheated steam boiler, which is mainly used for the production of steam for plant protein powder. The ZOZEN design team configured the boiler system according to the actual needs of customers in different industries, especially some special process needs, to provide practical solutions for customers. For biogas and natural gas blending, ZOZEN provided the customer with an optional American zeeco ultra-low nitrogen burner to meet the design requirements and operational emission index requirements, as well as smooth and continuous operation.

szs gas fired boiler

Natural gas boiler in the chemical industry to produce industrial glycerin project, Corning Oil Technology Co., Ltd. needs gas steam boiler to provide stable steam for the distillation, decolorization, deodorization and other processes of purified glycerin. ZOZEN provided the customer with SZS series gas-fired steam boilers with a double-barrel D-shaped arrangement structure and a full-film water-cooled wall structure for the boiler combustion chamber, which is gas-tight and has better heat transfer. Meanwhile, the reasonable steam ladle size and steam-water separator configuration can effectively reduce the steam with water, which significantly improves the steam quality. ZOZEN SZS series gas steam boilers provide stable and high quality steam for chemical plant projects.

In fact, in the process of industrial boiler operation, in order to reduce the operating cost of the boiler, that is, to reduce the gas consumption of the boiler, then you have to choose a thermally efficient natural gas boiler. Wuxi ZOZEN Boiler Factory focuses on developing steam boilers and hot water boilers, with rich experience in industry service and absolute strength, and the products are sold to more than 100 countries and regions at home and abroad, which fully proves that the quality of ZOZEN gas boilers is trustworthy.