Industrial steam boilers can use a wide range of fuels, including natural gas, coal bed methane, liquefied gas, biogas, clear oil, diesel, heavy oil, as well as coal and biomass. Usually dual-fuel boilers mostly refer to industrial boilers that use a mixture of oil and gas, which can be natural gas fuel or artificial gas fuel, natural gas and diesel, bulk oil and gas boilers can also be heavy oil or light oil, this type of boiler can make enterprises more flexible in fuel selection and effectively help enterprises reduce boiler operation and production costs.

It is a kind of combustion system that can burn both gas and oil. The operation principle is also to send fuel and air into the furnace chamber according to the required concentration, speed, turbulence and mixing mode, and make the fuel to be able to fire and burn stably in the furnace chamber, so as to heat the heated surface of the boiler and transfer heat to the medium in the barrel, and then produce steam, hot water and high temperature heat-conducting oil, etc.

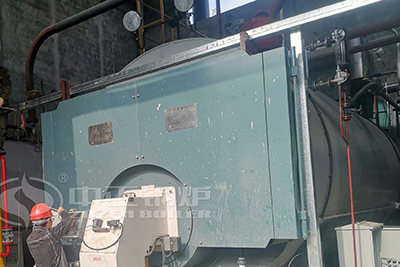

diesel gas fired water tube boiler

The dual fuel boiler consists of boiler body, burner, electric control cabinet and pipeline valve instrumentation and feed pump, etc. The steam boiler adopts the mature structure form of horizontal internal combustion three-return wet-back type, the flue gas stays longer in the boiler, which effectively improves the thermal efficiency of the boiler. The boiler body adopts large corrugated furnace gall, which increases the diameter of the furnace chamber in the original traditional design, increases the amplitude heat exchange area of the furnace chamber, fully burns the fuel, and reduces the amount of harmful gas generation. Steam boiler in the use of a high percentage of production, heating (heat exchanger), etc., more functional, compared to ordinary boilers with a high degree of automation, to achieve unattended operation, equipped with multiple interlock protection to enhance safety.

Steam boilers with dual fuel diesel and gas system are used for projects in the pharmaceutical industry. ZOZEN is a boiler supplier for pharmaceutical plants, and steam boilers are important energy equipment for pharmaceutical production lines, mainly providing steam support for production processes such as concentration and drying of pharmaceuticals, and also becoming one of the main energy consumption equipment for the company. According to the actual gas demand of the customer, ZOZEN Boiler customized two sets of SZS series natural gas boilers and one WNS series biogas boiler for the pharmaceutical production line as a steam boiler solution, including thermal deaeration system, feed water system, main steam system, air and smoke system and other supporting services.

szs series natural gas boiler

Oil and gas boiler series products are ZOZEN boilers energy-saving and environmentally friendly classic boiler type, with excellent manufacturing process, reasonable structure design and stable performance, which has won the unanimous approval of the market. At the same time, the boiler is equipped with imported low-NOx burner, using new combustion technology, without FGR to control NOx stably below 30mg/Nm3, with the outstanding advantages of low nitrogen and low energy consumption, with the boiler intelligent control system, can adjust the combustion scheme at any time according to the change of working conditions, and effectively reduce energy consumption for users. ZOZEN boiler will continue to deepen the boiler industry, continue to output more high-performance boiler products, to provide more pharmaceutical companies with green gas steam boiler solutions.